How Dynamic Positioning helps offshore vessels remain stable and safe

Qasim Masood AFNI, Head of Qualifications Marine and Offshore at The Nautical Institute, examines the wide variety of ships, support vessels and specialist craft that use Dynamic Positioning to ensure their safety in the offshore oil and gas industry

T he technology behind Dynamic Positioning (DP) has been gaining traction across many different industries and applications for decades now. One particularly key point in its development has been the critical part it has played – and continues to play – in keeping drilling and offshore oil and gas ships and vessels safe. The use of DP as a safety tool has made the versatile technology extremely popular in the offshore sector. This article outlines just some of the specialist vessels employed in this sector that use DP, and ways in which that technology is important. This is not a comprehensive list – and there are many other DP applications in other sectors as well – but it gives some idea of the far-reaching impact of the technology and the opportunities that it offers.

Drill ships

A drill ship or vessel is mainly used for drilling operations, with some used for exploration, and some to help maintain existing oil wells. Traditionally, they can be bottom standing, self-elevating, moored or controlled by DP. Drill ships that use DP can hold their position extremely effectively. This offers a safer way of steadying the vessel, compared to traditional mooring methods and cumbersome anchor handling techniques. There are economic advantages to using DP on drill ships too, such as weight savings due to not having to factor in heavy mooring arrangements. This adds value in deep-water, large-scale oil wells, as well as in small oil fields. There are still some safety factors to consider, however, such as the risk of the vessel losing its position due to a failure in the DP system. Preventative measures must be taken to mitigate against this risk.

Diving support vessels

Diving support vessels act as a base for offshore diving work. They are equipped with diving equipment and used to support underwater work, such as maintaining oil pipes and continuous intervention measures at subsea level.

Diving support vessels rely on DP to keep them steady in one position. This ensures the safety of the divers and the viability of the work being performed. Subsea launch/recovery work, whether it occurs in open waters or near an asset, is risky, and divers' lives may depend on the vessel remaining in one position (see incident report, p 7). Safety must be the top priority

Remotely operated vehicle support vessel

A DP vessel acting as a support vessel for a remotely operated vehicle (ROV) in deep water will use position reference systems, wind sensors, motion sensors and gyro compasses to help it to keep track of the ROV. The DP systems help the DP vessel launch, operate and recover the ROV safely. Depending upon the type of ROV being handled, it may have its own launching and recovery system. In order to track or follow the ROV during operations, the ROV support vessel uses a DP mode called ‘follow target’ or ‘follow sub’. It is important for the ROV control and the DPO to work closely together to avoid the ROV becoming entangled with the taut wire or hydroacoustic position reference (HPR) beacon/s connecting the support vessel to the ROV.

Cable layers and pipe layers

A cable layer, or cable-laying vessel, is used to position cables or repair those already in place. These vessels work in both shallow and deep waters and, in some cases, in ice waters. Onboard cable carousels can store thousands of tons of cable at any time. While laying/repairing cable, the vessel uses DP in ‘track follow’ or ‘auto track’ mode to trace the cable exactly. Pipe-layers, or pipe laying DP vessels require additional input over and above the usual DP sensors. The vessel’s DP system must be able to sense and compensate for additional forces caused by pipes acting on the DP system, and has special sensors to allow for this. Pipe layers may also use support vessels and equipment such as ROVs, cranes, subsea cranes and survey and inspection activities.

THE USE OF DP AS A SAFETY TOOL HAS MADE THE VERSATILE TECHNOLOGY EXTREMELY POPULAR IN THE OFFSHORE SECTOR

Supply vessels

Offshore support vessels (OSVs) are speciality ships designed to provide logistical support to offshore facilities and platforms. It is extremely useful for a vessel to be able to hold position without mooring while supplies etc. are transferred. The class of DP used by each one is influenced by the types of supplies being carried, the size of the vessel in question and the regions in which it operates. What remains consistent, however, is the key role that DP plays in ensuring their safety and that of the offshore platforms they work alongside.

Well-stimulation vessels

Well-stimulation vessels provide offshore intervention by injecting high-pressure chemicals into an oil well to stimulate productivity, so keeping them stable and in one position is vital. These vessels may be fitted with chemical tanks and blenders.

Dredgers

Dredgers are used to dredge out a particular area, which may need to be a very specific shape and size – for example in port construction or maintaining or widening a channel. The accuracy of dredgers can be enhanced by using DP. The vessel’s class may depend upon the type of dredging operation and the level of accuracy it requires.

Rock-dumping vessels

A rock-dumping vessel covers entrenched pipeline or cables with rocks for safety purposes. Again, this requires DP support to maintain position and accuracy during operations. Technologically advanced rock-dumping vessels may also use ROVs to assist in this work.

Anchor-handling vessels

Anchor-handling vessels are used to control the anchor on offshore installations. They are more commonly known as AHV or AHTS.

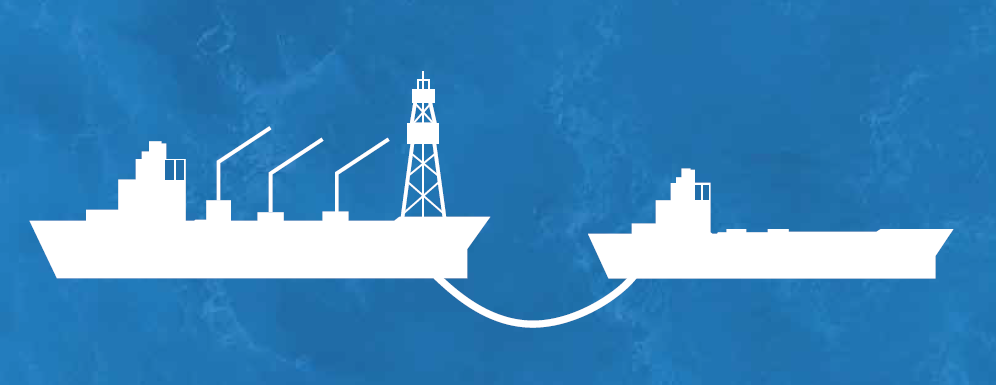

Floating production storage and offloading vessels (FPSO) and shuttle tankers

(FPSO) and shuttle tankers An FPSO is used for producing and storing oil, which must then be offloaded to a shuttle tanker or a pipeline. Transfer to the tanker is simplified by the use of a DP system, which helps the FPSO maintain a riser angle for safe operations. A shuttle tanker travels between shore and offshore to offload the oil produced by the FPSO. Both FPSO and shuttle tankers use a special mode of DP called ‘weathervane mode’ to maximise their safety during operations.

Heavy lift or crane vessels

Heavy lift or crane vessels are used in offshore industrial missions where large loads need to be picked up/placed down. Most large lift vessels work at surface level or at very shallow depths. Heavy lift/crane vessels must have special arrangements for ballasting and de-ballasting during lifting operations in order to ensure stability.

Accommodation barges / vessels

Accommodation vessels/barges provide accommodation to workers on an adjacent rig/vessel/facility. Sometimes, accommodation on the facility itself is insufficient or unsafe, so these barges are positioned nearby instead.

| These are just a few of the operations where DP-enabled vessels vessels provide specialised services – and in each and every one of these cases, safety is the priority. IMCA M 117 Code of Practice for The Training and Experience of Key DP Personnel highlights the need for appropriate training for DP professionals worldwide. |