Free Article : Traditional route, modern technology

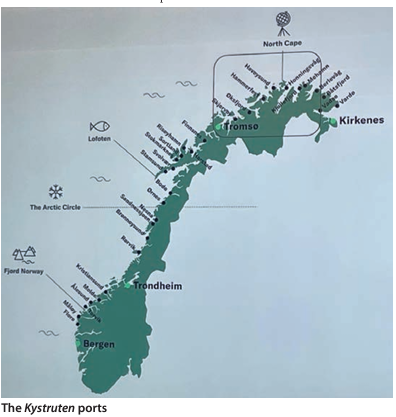

Thirty four ports over 11 days makes for a busy round-trip schedule, but that is just the normal routine for the ships that ply the 130-year tradition of the Norwegian coastal route, or Kystruten.

David Reid MA FNI

Today, the route is shared between two Norwegian companies, Hurtigruten and Havila. Both provide the traditional port to port service for Norwegians who need this vital maritime link, along with a growing tourism service for global travelers who are seeking a different type of cruise experience.

Sailing in such a sensitive environment, moving towards green technology and operations is very much on the agenda. On a recent passage on the Havila Capella, I was fortunate to interview the Master, Captain Brynjard Ulvøy, and to learn more about the unique design features of this innovative ship.

Design brief

The Kystruten begins in Bergen and weaves its way in and out along the coast passing the Arctic Circle to reach Kirkenes on the Barents Sea, just 7km from the Russian border. One of the most modern vessels working the route is the Havila Capella. The ship was built in Türkiye at the Tersan shipyard in 2021 to a design by Havyard, Havila’s in-house-design team. Registered in Norway, and carrying a complement of Norwegian and Scandinavian officers and crew, the ship can carry 640 passengers in 179 cabins.

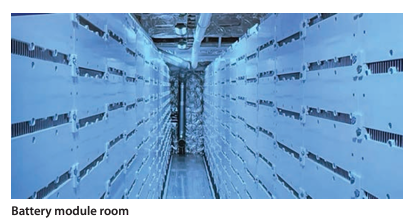

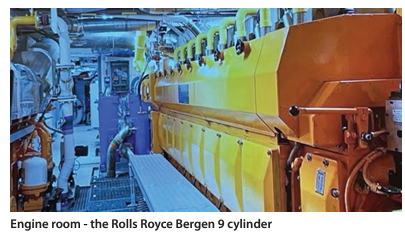

The key focus of the design is the eco footprint. This all-electric ship generates electricity from four engines using liquefied natural gas. In addition, the ship has a modular battery pack that enables it to run entirely on battery power for a period of up to four hours. In routine operations, the ship operates in hybrid mode with electricity generated from the engines complemented by battery power. The entire propulsion and power generation is a turnkey installation by Rolls Royce. Four engines of the Bergen type, two with 6 cylinders and two with 9 cylinders, offer inherent flexibility to precisely load manage the power requirements. As we approached the port of Hammerfest only two of the 9-cylinder Rolls Royce Bergen engines were running, and 38% of our power was coming from the four battery modules.

The 6.1-megawatt hour lithium-ion batteries are arranged so that individual packs can be swapped out – an important feature, given that the latest battery technology already yields 30% more than the original battery packs, which are themselves just two years old. The Master and Chief Engineer fully expect their onboard batteries to deliver more and more power as battery technology evolves. In conjunction with this, they expect that in future they will have super-fast charging available at ports where they stay for an hour or more. The effect will be greater use of battery power and reduced consumption of LNG. Havila intends to use biogas when it is available, and the vessel also has the option to run on green hydrogen and ammonia as alternatives to LNG. The focus is on a future with zero emissions.

Before taking command of this ship, both the Master and the Chief Engineer underwent training that included LNG bunkering practices and sea time on an LNG powered ferry. They both said that the paramount safety benefit of the hybrid engine model was the elimination of blackout risk. The system switches immediately to battery power, with no loss of propulsion, critical systems or passenger safety. For this reason, they always run in hybrid mode. Clearly this is a giant leap ahead for those of us who have experienced the trauma of blackouts and the worrying gap between failure of the main engine and emergency generator startup, especially the lack of propulsion.

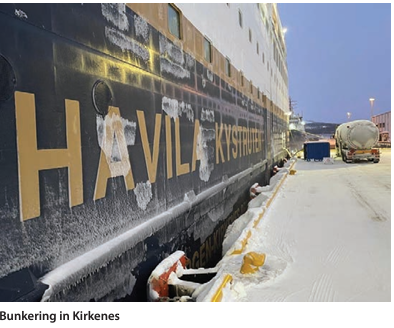

LNG bunkers are taken at Kirkenes and in Bergen. The two fuel tanks are located below the cargo deck and can carry sufficient fuel at -140c for a 12-day voyage. In Kirkenes, a 3-day supply of 100 m3 was delivered by two road tankers, taking three hours to bunker. Kirkenes is a six-hour road journey from the Equinor LNG terminal at Melkoya island supplied from the Snøhvit gas field.

Havila is very mindful of making their ships carbon friendly. But their efforts to be eco-minded also extend to smaller details, going well beyond the question of propulsion. They do not print daily schedules because they are mindful of the waste. They also rotate cabin cleaning to every other day unless the guest has a special need. Guests are reminded to use the same cup for their second cup of coffee. The team onboard convey all of these ideas and requests in a collaborative way that encourages everyone onboard to join in the eco-Voyager experience.

A busy port schedule

The 2,645 nautical mile route covering 34 ports over 11 days results in as many as eight port calls per day keeping the team onboard very busy. Clever design really helps here; the mooring stations are all sheltered spaces and have small platforms at the bow that hinge outwards, allowing the mooring team to easily throw heaving lines ashore and maintain line of sight to tend to their lines. The ship has two rotating Azipull units and twin bow thrusters, and can manoeuvre alongside confidently even during adverse conditions – important in a schedule that has an average of six port calls per day. They always berth port side to, and the two side ports are positioned for simple operation, one for freight and one for passenger access. A self-sustained retractable wide gangway leads ashore from deck 4.

Cargo is an important part of the service and is subsidized by the Norwegian government as part of a 10-year contract, but it is limited to high value goods shipped on euro-pallets. Havila Capella can carry 180 euro-pallets, of which 30 can be kept in a refrigerated space. At each port, a shore-based forklift appears for a few minutes and the pallets are moved on or off. Cargo operations can last less than five minutes. While the vessel has capacity for 12 cars, Havila will not transport electric vehicles or hybrids because of the fire risk, as they cannot contain a battery fire from a car on the cargo deck.

Norwegian weather can range from the sublime to the adverse, and the crew have to adjust as conditions affect safety and wellbeing. A recent southbound sailing was terminated at Trondheim because the sea conditions on the open coast were deemed too excessive, and passengers were given a ‘boat replacement bus’ service to Bergen. On our own voyage the inside fjord route was modified to an outer passage due to very high winds that made the inside route a safety concern. Havila gives full authority to the onboard team to make the right judgement. Safety first, rather than rigid adherence to an advertised commercial schedule is to be commended, and when explained in the proper manner, this is well received and respected by passengers.

Crewing and operations

The crew onboard consists of 18 people to navigate and operate the vessel, with a further 45 to 50 managing catering and guest services. Both operational and ‘hotel’ staff rotate every 22 days, changing at a port that is convenient to them. I asked the Master about his leadership philosophy to sustain positive social interaction. His reply was very simple: ‘Be yourself.’ For him, leadership has to create and sustain the right environment and then let everyone get on with their job.

Sometimes this means one on one encouragement over a cup of coffee – it is impossible to write a prescription for every possible situation. The onboard expedition team provide knowledge of all things Norwegian. At every daily briefing the passengers learn something about the Norwegian language and culture. Havila makes everyone feel welcome along the Kystruten. The crew share the love of their country while ensuring that the respect of the environment and the intrinsic value of safety is always on the mind.

David’s previous visit to the port of Kirkenes was in the summer of 1972 while serving as 3rd mate onboard the British ore carrier Finnamore Meadow – already an associate member of The Nautical Institute, which was then in its very early years.