Free Article: Big is Better?

The impact of tug size on handling small or medium sized ships

by Captain Henk Hensen FNITug power has increased considerably over recent decades. Today, some ship handling tugs have a bollard pull of more than 100 tons. In addition, high tug power can be installed in ever smaller compact hulls. As a consequence, the composition of tug fleets is changing, and increasingly, pilots are complaining about the absence of the smaller tugs that are needed to handle smaller ships in a smooth, safe and efficient way.

Change in tug fleet composition

The increase in maximum tug power is a consequence of the need to assist and escort very large tankers, bulk carriers and gas carriers, while the latest container carriers have such a large windage, that in case of strong winds much tug power is needed. While in previous years, a fleet of conventional tugs would be made up of less powerful tugs than today, it would also – importantly here – include a number of smaller tugs to assist smaller vessels.

For the purposes of this article, we will assume that a ‘modern’ tug fleet consists of azimuth stern drive (ASD) tugs, although the discussion which follows applies to most other tugs with azimuth thrusters as well, such as azimuth tractor drive (ATD) tugs. ‘Small or medium sized ships’ refers to vessels up to about 160 metres in length.

Let us take the tug fleet of the port of Rotterdam as an example. Before the arrival of modern tugs with greater power in around 1980, there were five classes of tugs in the Eastern part of the port, with an additional class in the Western part of the port.

| Class of tugs | Tug power | Estimated bp | To handle ships |

| C tugs | <300 hp | <5 tons | Up to 101 metres |

| B tugs | 300 hp | 5 tons | 100 – 132 metres |

| A/B tugs | 300/400 hp | 5/6 tons | 133 – 142 metres |

| A tugs | 400 hp | 6 tons | 142 – 167 metres |

| Super A tugs | 600 hp | 9 tons | 167 – 199 metres |

| 900 hp tug | 900 hp | 12 tons | 199 – 242 metres |

In the Western part of the port where the largest deep draught tankers and bulk carriers berth, stronger tugs were available: 6 x 30 tons, 4 x 35 tons and 2 x 40 tons bollard pull Voith Schneider tugs. It is amazing to see how small tugs handled large ships. For instance, tugs of only 600 hp were assigned to ships of over 200 metre length. Even with the relatively small difference in tug power across the tug fleet, small ships were handled by the smaller tugs and larger ships by the somewhat more powerful tugs.

Present situation

With a tug fleet consisting solely of modern powerful ASD tugs, it is frequently the case that these powerful tugs also have to handle smaller ships. Even when the tug is not equipped with slipping clutches, an experienced tug master can manoeuvre these modern tugs very gently. This is a prerequisite when handling smaller and light ships, otherwise the ship manoeuvres may be spoiled. Proper training is therefore essential – but there are other consequences of the use of large and powerful tugs to handle small and medium sized ships, which will be discussed below.

Response time

Short response times are an important factor in the smooth handling of small and medium-sized vessels. This is one of the reasons why smaller tugs are preferred.

Tugs with a high bollard pull regularly have to operate with reduced power to avoid overloading the ship’s deck equipment due to high forces in the tow line. This is often needed when handling large ships, but always for smaller ships. See Figure 1, where an ASD tug with a bollard pull of 80 tonnes is assisting a relatively small vessel with deck equipment with an estimated Safe Working Load (SWL) of around 30 tons. This needs the powerful tug to reduce its pulling power by more than 60 per cent – although reduced power can also be used in combination with tension control on the towing winch, if tugs are equipped with it. The reduced power will lengthen response times.

Today’s small ASD tugs are much more powerful than the old ones listed in the table left, with a bollard pull of, let us say, 20 tonnes. The Safe Working Load of deck equipment of ships up to approximately 160 metres is around 30–45 tons. In other words, a smaller tug will not need to reduce its power to keep ship bollards and fairleads intact.

It can therefore be expected that small tugs will be able to react considerably faster than large powerful tugs when assisting smaller vessels.

Another reason for that is that tug masters of powerful tugs have to apply the high power carefully, which is less of a concern for smaller tugs.

Sidewash

Another important aspect is the availability of slipping clutches (also called speed modulating clutches) and controllable pitch propellers. If an ASD tug is equipped with slipping clutches it can regulate propeller rpm stepless to zero or from zero up.

When decreasing speed to a minimum the thrusters stay in the same position (as shown in Figure 4, overleaf), while propellor rpm is decreased gradually till the required speed has been achieved. If a tug equipped with controllable pitch propellers decreases speed, rpm and/or propellor pitch is regulated in such a way that the required minimum speed will be achieved.

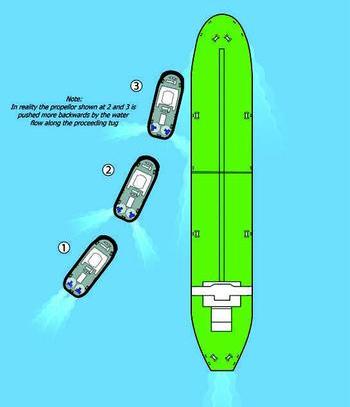

A tug that is not equipped with slipping clutches or controllable pitch propellers manoeuvres differently. This is shown in Figure 3 where an ASD tug without slipping clutches is approaching a ship which has some headway. During the approach the thrusters remain clutched in, and propeller rpm is at its minimum. To reduce speed further the thrusters are set at an angle (see nr. 2). Finally, the thrusters are set almost perpendicular to match the speed of the ship (see nr. 3). Steering is still possible by setting one thruster somewhat ahead and the other somewhat astern.

At the final approach (nr 3) the propeller wash is hitting the ship’s hull – this is clearly visible in Figure 1. Especially with a light ship, this can disturb the planned manoeuvre.

The strength of the effect depends on whether the tug has high or medium speed engines. The effect is greatest with high speed engines, and of course high power. An example:

A typical situation:

| RPM (engine) | Min | Max |

| Medium speed engine | 250 | 1200 |

| High speed engine | 500 | 1800 |

Assuming propeller rpm at maximum speed is 200, propeller rpm at minimum speed with the same reduction is then:

Medium speed engine (reduction i = 6): 250/6 = 41.6 rpm

High speed engine (reduction i = 9): 500/9 = 55 rpm

If we take an ASD tug of 70 tons bollard pull with a high speed engine, towing force at idle speed is then: 552/2002 x 70 = 5.3 tons, which means 2.6 tons for each thruster.

This is the same as a class A or B tug of the type mentioned above pushing with half power against the ship hull.

Furthermore, depending on the angle of inflow, the propeller wash may create an area of low pressure along the port side aft of the ship, pushing the stern to port. All unwanted influences on the ship.

The effect of lower powered tugs will be proportionally less. For example, a small low-powered tug of 20 tons will create a side wash force of, in this case, only about 0.7 tons.

It can be concluded, that for handling small/medium sized ships less powerful tugs are needed, preferably equipped with slipping clutches.

Displacement

If the assisting tugs are towing on a line, for instance one at the centre lead forward and one at the centre lead aft, they can give steering assistance or control the ship’s speed. They are not in contact with the ship and how they operate depends on the tug master’s experience.

Do these tugs have an effect on the manoeuvring of the tanker?

This may well be the case – although again, the extent of the effect will depend on the size of the tugs in relation to the size and displacement of the tanker.

When tugs towing on a line operate with utmost care, there will be no problems. But it may happen that for some reason the tug makes an uncontrolled movement, causing the line to tighten. This may result in unwanted movement of the ship, for instance a speed increase or a course change.

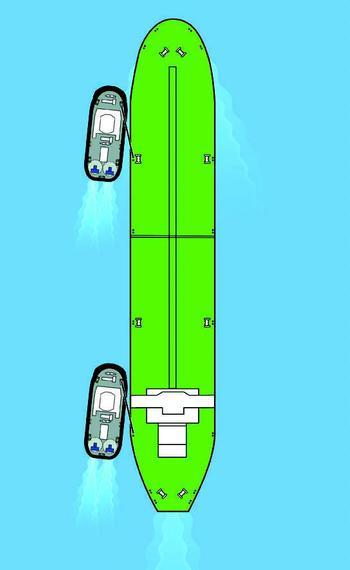

The tugs can also operate with the push-pull method. In that case, when the ship is approaching the berth, the tugs are usually made fast and are lying alongside as shown in figure 4, below.

In this situation, the tugs may hinder course keeping or delay course changes. For instance, when making a turn to starboard the forward tug has to move with the ship and the aft tug has to be pushed away, causing a lower rate of turn. The effect will be even more pronounced if the towline of the forward tug is coming tight.

In addition, when the tugs shown in figure 4 are proceeding with the ship under an angle, hydrodynamic effects will play a role and will also affect ship’s course keeping ability or course changes. Skegs underneath the tugs will increase this effect.

The larger and more powerful the tugs, or the smaller the ship’s draught, the larger the disturbing effect can be.

Let us have a look at the impact of tug size, in this case displacement. A tanker of 145 metres has an estimated displacement:

when loaded about: 27000 tons

when ballasted approximately: 17500 tons.

Large ASD tugs such as the Damen ASD 3212 have a displacement of 800 tons. With two tugs, as in Fig 4, this is a total of 1600 tons. In case of a ballasted ship, almost 9% of the ship’s deadweight is hanging alongside. Where smaller tugs are used, for instance the ASD 1810, it is only 3%. That is three times better.

In other words, the impact of the larger tug on the ship is three times higher than that of the smaller type of tug, assuming the same approach speed. This applies to situations as discussed where the tug comes, or lies, alongside a ship and when towing on a line. The higher power of the larger tug may even worsen the situation. So, again smaller tugs are preferred for handling small and medium sized vessels.

Course instability

Due to the high power installed in present tugs, stability – which was already an important concern for tugs – has become even more important. To increase stability, tugs with azimuth thrusters have become wider. However, such wide tugs have become course unstable as a result. It is a risky situation for a tug when operating close to a ship having headway and coming under the influence of interaction effects. It requires a tug master to be very attentive because frequent steering actions are needed, particularly for the more course unstable widerbodied tugs. A moment of inattention from the tug master may bring the tug in contact with the ship. Near the bow of the ship this can become catastrophic for the tug and problematic for the ship, while contact at other locations may disturb the ship’s manoeuvre, or cause damage to the ship unless the tug is equipped with good fendering. Again, the smaller the tug, the smaller the disturbing effect on the ship, and the lower the ship’s speed, the lower the risks.

This again shows how important it is that tug masters have a good practical training.

Height

Another point is the height of the tug’s bow. The bow of a large tug pushing at the side of a small ship may be too high for it, or may damage the ship’s railing (see figure 5).

What has to be done?

It has already been shown how important tug master training is. Proper ship handling with tugs requires thorough training by qualified instructors and optimal communication and cooperation with the pilot.

Some of the negative effects of large tugs assisting small or medium sized ships can be prevented or minimised through good training, but certainly not all. At the same time, if either training or communication is lacking, the negative effects of handling small ships with large tugs will increase considerably.

‘Big is Better’ is certainly not true when it comes to tug assistance for small and medium sized ships. Such ships should not be handled by large powerful tugs, such as today’s ASD and ATD tugs or similar of 40–100+ tons bollard pull, due to the risks outlined above, especially when thorough training of tug masters is lacking.

Ships up to approximately 160 metres in length should ideally be handled by more suitable tugs, smaller and less powerful, and preferably having speed modulating clutches or controllable pitch propellers. These tugs are also less costly to purchase, and the cost of fuel and maintenance is lower. A trend of building smaller ASD tugs can already be observed in the Netherlands, France and some other countries. These tugs have enough bollard pull to handle the ships in question safely.

Of course, the economic viability of developing a fleet including smaller, less powerful tugs depends on the number of small and medium size ships that call at the port. The more smaller and medium sized ships that call at the port, and the more frequently such ships use tugs, the larger the possibilities for smaller and less powerful tugs.