990X2 DNV Corrosive Cargo in Holds

Corrosive Cargo in Holds

DNV Casualty Information Notice

MARS1999

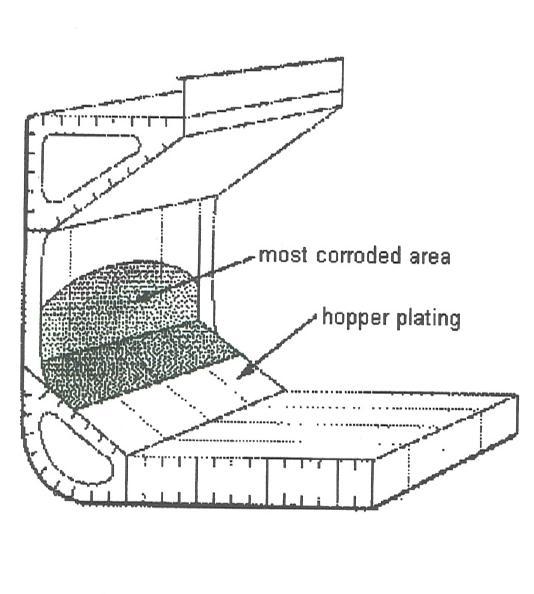

Upon survey of all cargo holds after a transport of sulphur cargo, serious corrosion was found. On the inclined plates of the hopper tanks and in the lower hold and the lower stool of the transverse bulkhead, extensive damage in the shape of groove corrosion was found with depth up to 9mm in places.

Probable cause

The main cause of the damage was considered to be damaged coating in combination with sulphur cargo. Sulphur, moisture and oxygen form sulphuric acid, which attacks steel. The cargo holds were originally painted, but surfaces had been damaged by grabs during previous unloading operations. Further, the cargo holds had not been properly cleaned and the paint not properly maintained after previous sulphur cargoes. Thus bare steel was exposed to attack by the corrosive cargo. In addition, the cargo holds had not been adequately ventilated. Where the hold surface was without paint, a more general but still significant corrosion would have taken place in way of the cargo as indicated in the sketch below.

When trading with bulk cargoes that may be corrosive, the following precautions should be taken in order to avoid serious corrosion damage in cargo holds.

The cleaning after discharging should be carried out properly, in particular when the previous cargo was sulphur.

Prior to taking corrosive cargoes, the coating in cargo holds should be dealt with as necessary.

The cargo should be kept as dry as possible during the loading and transit.

The hatches should be confirmed weathertight and the holds adequately ventilated.

A few examples of cargoes that need special attention in order to avoid problems mentioned above are listed below:

Ø Sulphur in bulk

Ø Copper concentrate (contains sulphur),

Ø Coal (contains sulphur),

Ø Petroleum Coke and Iron Ore.