202519 Strong currents require strong berthing measures

Providing learning through confidential reports – an international co-operative scheme for improving safety

As edited from TSB (U.S.A.) report MIR 24-25A bulk carrier had arrived at a river berth, bow upstream, to load coal. Light draft was close to 9.3m aft and the water depth at the berth was near 15.5m, which gave an UKC of 6.2m. The river was at recognised high water levels, which increased the strength of the river current, so extra lines were installed fore and aft and two ‘hold-in’ tugs were positioned on the outboard side.

The mooring lines were monitored during loading to ensure the vessel was always tight to the berth. During the loading process, the port captain boarded and informed the Master that the river water height was now below a critical level and falling. This made the loading terminal’s high-water loading plan unnecessary, so hold-in tugs were now not required. The port Captain asked the Master to release the aft tug, and the Master agreed.

Later that day, the ship’s agent contacted the Master, stating that ‘the terminal no longer requires your vessel to have any hold-in tugs alongside.’ The port captain also communicated to the Master that if the tug was retained it would be solely for the shipowner’s account instead of the charterer. Given this information, but against his intuition, given that the strength of the river current was now at between 3 and 4 kts, the Master released the forward tug at 15:00.

At 00:50 the next morning, cargo loading shifted to the final hold. At about that time the draft readings from the dock were 11.3m forward and 14.7m aft.

About one hour later, the crew found that the lines forward were very tight, and the bow had come away from the dock slightly. The crew tried to heave on the breast lines, but because the lines were already very tight, the vessel’s electrohydraulic mooring winches could not heave in. The Master was informed that the bow had come off the dock by about 1.5 metres and they could not bring the bow back alongside with the winches.

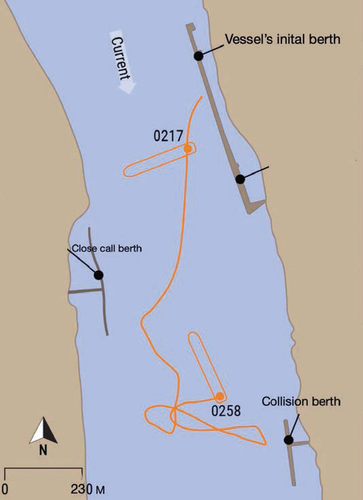

The Master went to the bridge and called for immediate tug assistance. The velocity of the current was now approaching 4.5 knots. Within minutes, the vessel’s bow began to move farther to port, away from the dock, while the stern remained alongside. At 02:10, the Master summoned all crew on deck. On his way to the bow, an officer saw the forward mooring lines paying out; smoke and sparks could be seen coming from the port side winches, so he stopped as it was no longer safe forward.

The Master asked for immediate engine readiness, but as the bow continued to move out into the river, greater tension was now being placed on the stern lines which began to part. The vessel then broke away from the dock and the Master ordered the anchors away. At 02:16, main engine propulsion control was transferred to the bridge. Once safe to do so, crew went to the bow and released the starboard anchor, which was already hanging out of the pocket. The anchor was let go to one shot (27.5m) on deck.

Two tugs had now approached. Given the parted lines in the water on the vessel’s starboard side, they were unable to approach the side of the vessel for fear of fouling their propellers, but were able to keep the vessel from drifting onto an unoccupied dock downstream.

Soon, the port anchor was in the water. The brake was applied at 4 shots (110m), but the brake could not hold the chain, and the port anchor continued to pay out under heavy tension until the brake held the chain at 5 shots on deck, still under heavy strain.

By 02:48, the bulker was drifting downriver about 4 knots and closing on another berth. Both tugs continued efforts to stop the vessel’s drift downstream, but the bulker nonetheless collided with some barges tied up at this berth. After the collision, a third tug arrived, and the bulker was brought under control until a river pilot arrived and the vessel conducted to anchorage.

The investigation found that the probable cause of the breakaway of the bulk carrier from the dock was the bow coming off the dock during cargo loading, thereby exposing more of the vessel’s underwater hull to the strong river current.

Lessons learned

- The force of a current on the hull of a vessel increases in a nonlinear fashion in relation to the current speed (ie to the square of the velocity). Beware of this hazard!

- It is important to ensure that berthing lines are kept well taut as a vessel loads and sinks lower. This increases the surface area of the hull to the current and hence the force acting on the hull.

- The increase in the force on the hull as the speed of the current increases is non-linear. A reduced UKC adds a multiplying factor to the resultant force. In this case, approximately 1.2X (source: Capt S S Chaudhari)

- In such conditions, it is good seamanship to keep propulsion, thrusters, and steering systems on short standby and have anchors ready for immediate use, even if not required by the loading facility.