202511 Mooring fatality

Providing learning through confidential reports – an international co-operative scheme for improving safety

As edited from MAIB (UK) report 18/2024Under pilotage, a bulk carrier was coming alongside a berth for loading. As they approached, the pilot explained to the Master the required manoeuvres. Two tugs would assist with the berthing operation. The vessel would be moored port side to the berth with two springs and four head/stern lines forward and aft, respectively.

Once the vessel was alongside with the first springs fore and aft fastened, the port control advised the pilot that the vessel needed to move 30m astern to align with the cargo loading arm. The Master instructed the mooring party crews accordingly. The vessel’s engine control was set to dead slow astern, and it began to move back, eventually reaching a speed of 0.5 knots. During the manoeuvre, the forward mooring party heaved in the slack on the forward spring and the aft deck mooring party slackened the aft spring.

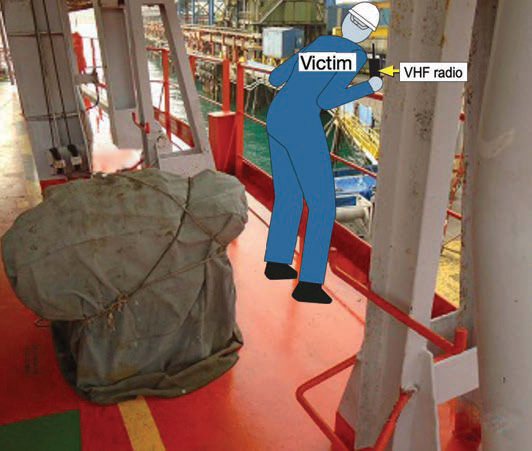

A few minutes later, the officer in charge of the aft mooring party positioned himself near the accommodation ladder and looked over the side rail directly above the slack spring line while using a VHF radio. At that moment, the spring line tightened, then slackened and then came under tension once more. A loud bang was heard as the line suddenly released and recoiled vertically upwards.

The officer was struck under his chin by the recoiling spring line. He was lifted and thrown backwards, his head striking the accommodation ladder behind and above his former position.

The victim was found lying in a large pool of blood and the alarm was raised. Within seconds, medical assistance was requested from the port and the tugs directed to hold the vessel alongside. The port’s medical team boarded within minutes, but the victim was pronounced deceased at the scene.

The investigation found, among other things, that:

- As the vessel moved astern under its own power the aft spring line became trapped on the dock fendering.

- As the line tensioned and the vessel momentarily moved away from the jetty, the line released (like a bow string) upwards at an estimated speed of 65km/hr leaving the victim minimal opportunity to move out of its path.

- The use of engines while running lines is generally avoided during mooring operations to reduce the risks of mooring lines being drawn into a rotating propeller or rapid tensioning of a line.

- The terminal’s mooring procedure specifically stated that there should be no ship running manoeuvres, implying that a vessel should not use its engines while positioning alongside. It is probable that the Master of the vessel was unaware of this requirement because a copy of the terminal mooring procedure had not been provided.

- Given that vessel’s engines were apparently often used while manoeuvring alongside berths at this port, it is also probable that the pilots had not been provided with the mooring procedure either.

Lessons learned

- This accident is reminiscent of MARS 201870 where the victim, also at the aft mooring area, looked overboard to gain a better view and was struck by the released spring under tension.

- This accident is testament, once again, to the dangers of mooring work. Be aware of your environment and the potential hazards.

- The energy within mooring ropes can easily injure or kill. Always use extreme caution when working within the mooring area.

- If there is no clear, unimpeded path from fairlead to bollard, beware of increased tension in the line. If necessary, slacken the line until the obstruction has been cleared.