201621 Small oil leak has major consequences

Edited from official UK Marine Accident Investigation Branch report 22-2015

A ferry was entering port when the starboard controllable pitch propeller stopped responding to the controls. The shaft was de-clutched and the two starboard main engines stopped. The prevailing weather conditions were such that the Master was able to proceed using one propeller shaft and one bow thruster.

The starboard controllable pitch propeller system stand-by pump was subsequently started to maintain oil circulation. Shortly afterwards, a joint in the system’s pipework ruptured, spraying oil onto the hot exhaust uptakes and turbochargers. The oil ignited, causing a significant fire in the main engine room, which was subsequently evacuated. The general emergency alarm was sounded and the passengers were mustered at emergency stations. The ferry berthed safely and the fire was extinguished using the ship’s hi-fog system and a fire hose. The passengers and cargo were disembarked normally.

The investigation found, among others, that:

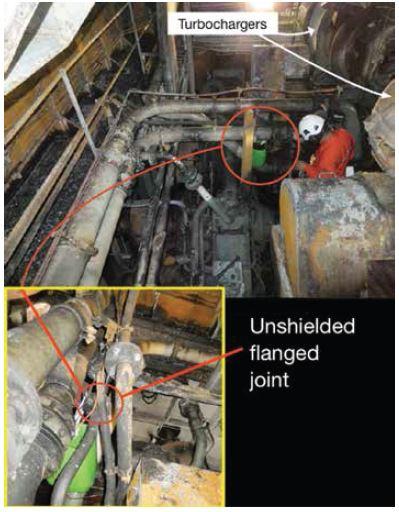

- The back pressure valve in the starboard controllable pitch propeller hydraulic system had jammed shut, causing the oil pressure in the return line from the oil distribution box to rise; a flanged joint in the return line from the oil distribution box was unable to withstand the high pressure that resulted, spraying oil onto hot engine parts.

- The joint that failed was not shielded to prevent a spray of oil in the event of failure. Although SOLAS now requires that, as far as practicable, oil lines should have the minimum of joints, be arranged as far apart from hot surfaces as possible, and be shielded to prevent oil spray onto hot surfaces, these control measures were not required at the time when the ferry was constructed. If an effective joint shield had been fitted, this would have prevented a spray of oil being released onto hot engine parts, thus no fire would have resulted.

- While the hi-fog system was able to tackle the fire in the immediate vicinity of the two main diesel engines, the fire was able to spread outside of this area. Combustible materials, including wooden packaging, that were located near the source of the fire were a contributing factor to the spread of the fire.

Lessons learned

- A specific risk assessment should be done in every engine room to determine the potential for, and protection from, oil under pressure reaching hot surfaces.

- Keep engine rooms as clean and neat as possible with combustible materials stored away from possible sources of ignition.