201503 Check your lead or lose your anchor

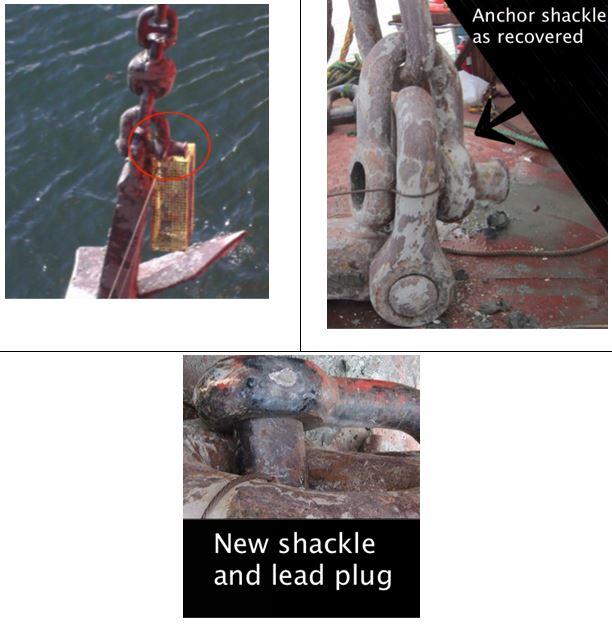

While preparing to depart anchorage and heaving the port anchor it was discovered that the end shackle pin was protruding from its normal position. The anchor wash was shut off to get a better view of the end shackle arrangement, and it was confirmed that the anchor was supported only by a small portion of the end shackle pin. The Master and Pilot decided to return to the anchorage area and lower the starboard anchor while awaiting further investigation. A spare end shackle and tapered pin was located onboard with certificate. The next day, a tug and barge came alongside and the vessel’s crew met with the foreman of the barge to determine a plan to replace the end shackle. A risk assessment and toolbox meeting was conducted and the job undertaken. A statement including pictures regarding the end shackle replacement was sent to Class.

The company investigation found that it was most likely that the lead seal of the tapered pin had worked itself loose and went missing. The pin securing the shackle bolt was then able to work itself loose. Although the company’s managed vessels had a procedure in their planned maintenance system for checking the integrity of the anchor joining shackle tapered screw and seal, it did not include any direction as to what the check should include or why it was required. Nonetheless, this job had been carried out annually without any discrepancies noted. The practice developed onboard provided for sighting the anchor and joining shackle from the main deck. However, given this incident, the practice was deemed insufficient to meet the requirement. In order to accurately check the security of the lead seal an up close physical inspection would need to be arranged. Company procedures were changed accordingly.