201259 Injury from detached fairlead roller

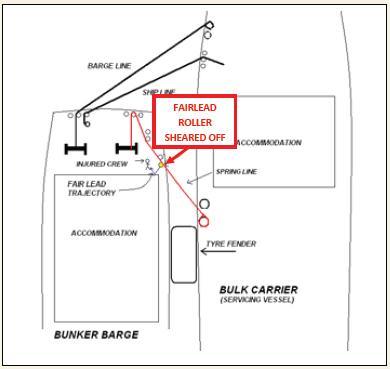

Just after midnight, a bunker barge moored on the starboard side of a bulk carrier at anchor off port limits (OPL), with two lines and a spring forward and aft. After securing the lines, the barge crew began passing the fuel hose to the receiving ship, in winds gusting to 15 knots and a maximum swell of 1.5 metres. Suddenly, a fairlead roller on the barge’s port quarter was uprooted from its base. It hit the accommodation bulkhead with great force, then ricocheted and hit the Bosun’s mate. The casualty was immediately taken ashore to a hospital and was diagnosed with severe contusive injuries on his right lower abdomen and inguinal region with arterial occlusion. Following emergency surgery, he was kept in hospital care for more than two weeks before being repatriated home for a further period of recovery.

Result of investigation

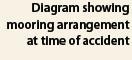

Due to the large difference in freeboard between the two vessels, the mooring lines from the barge’s deck were all leading upwards subjecting the roller to a combination of large cyclical sideways thrust and lifting force. Ultimately, material weakness and fatigue caused by corrosion and wastage within the roller’s body caused it to shear off from the base.

Lessons learnt

1 A proper risk assessment must be conducted before commencing mooring operations, taking into account the effects of sea state, difference in freeboard, lead angles of lines and prevailing circumstances and conditions;

2 Mooring plan must be jointly discussed and approved by both supplying and receiving vessels;

3 If additional safety measures are not considered to mitigate risks to an acceptable level, the bunker transfer must be cancelled / postponed;

4 Mooring equipment must be properly inspected and maintained as per a documented planned maintenance system (PMS).

Editor’s note: There have been many reported instances of sudden and catastrophic failure of roller fairleads on ships due to ineffective inspection and maintenance. Undetected corrosion and wastage can seriously weaken the base and mountings, especially when subject to frequent contact with / immersion in sea water, as can be expected on a low-freeboard bunker barge. Additionally, in the case of such vessels, due to the inevitable upward lead, mooring ropes / lines / hawsers can slide off the groove of open roller fairleads, so multi-angle roller fairleads or Panama chocks should be fitted instead.