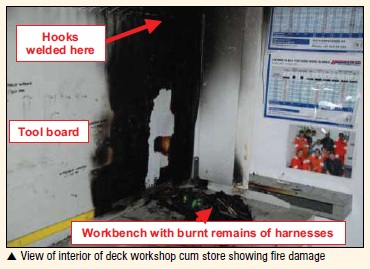

201217 - Hot work causes fire in workshop

A deck workshop/store on a survey vessel was a compact, stand-alone structure, located abaft the wheelhouse. It was originally designed as a store, but over the years, the crew had also installed a wooden tool board and a work bench against one of the bulkheads. Portable welding and other equipment was also stored in this space. Adjacent to the store was a designated storage arrangement for chemicals and flammable liquids. In order to re-arrange items inside the cramped space, the boatswain (bosun) planned to weld two hooks on the internal bulkhead frames directly above the tool board and work bench for stowing a crowbar. The bosun completed a permit for hot work form, which was approved by the OOW (2/O), who failed to detect several factual and procedural errors and did not conduct a proper discussion or risk assessment. Working alone, the bosun welded one of the hooks to the bulkhead and attended briefly to another errand. The second hook was then welded adjacent to the first one, this time with a seaman also present. Neither of the men paid attention to the cardboard box containing harnesses (made of flammable synthetic fibre) that was lying on the workbench directly under the weld site. They then left the area for a short break. Some minutes later, as the master exited the wheelhouse, he found thick black smoke billowing from the open door of the workshop. He shut the door, returned to the wheelhouse and informed the bosun on the radio that there was a fire in the deck workshop. While the bosun rushed to the site with the other ratings, the master sounded the fire alarm and ordered the 2/O to take the nearest fire extinguisher to the location. Upon arrival at the scene, the bosun opened the door and could see flames on the work bench through the dense smoke. He briefly entered the space and rapidly discharged a portable CO2 and a foam extinguisher. This was followed by a water jet from a charged fire hose and the fire was soon extinguished. n Editor’s note: Given the cramped space, a wellestablished fire and flammable materials located nearby, the bosun’s action was unsafe due to the hazards of toxic smoke, oxygen deficiency, burn injury, electrocution from damaged electrical circuits and fire spreading to outside the confines of the space. Only the designated fire-fighting team wearing approved fireman’s outfits and SCBA should approach and tackle a shipboard fire.

Immediate causes

1. No proper risk assessment was conducted;

2. Combustible materials were not removed from the worksite prior to the commencement of hot work;

3. No dedicated fire watch was in place either during the hot work or after it was completed. Root cause/contributory factors (as per findings of investigator): 1. Lessons learnt from previous fire incidents arising from hot work had not been effectively implemented (fires resulting from failure to clear combustible materials from the vicinity of hot work sites had occurred on four past occasions);

2. Personnel responsible for hazardous work not adequately trained in use of the permit-to-work system and risk assessment methods;

3. The company did not adequately monitor the quality of risk assessments performed, permits completed onboard and compliance with procedures related to the management of hazardous work;

4. The risk assessment and toolbox meeting documents and records were all maintained within a computer based (paperless) system. It was felt that printed material would have improved workforce understanding of safety issues, promoted more effective risk assessments and job execution at the work site.

Recommended action

Ensure that: 1. A system for the delivery of training in use of the permit-to-work system, risk assessment methods, and the general management of hazardous tasks is developed and implemented. The system shall include a review of training in general to determine if training is also required in other areas;

2. Management of hazardous work on board vessels is adequately monitored. Enforce compliance with the risk assessment procedures as stated in the SMS;

3. The definition of hot work (previously only gas-cutting and welding) is expanded to include burning, brazing, grinding, soldering, thermal resistance heating, etc;

4. It is clearly stated which activities are to be preceded by a risk assessment and management procedure for each department on board;

5. A fleet circular is issued informing all employees of the lessons learned from this incident, and these are also shared with the industry.