200882 The importance of eye protection

Source: UK P&I Club, Bulletin 605, 10/08

A seaman's eyesight survived a recent incident because he was wearing eye protection when a grinder disk shattered. Had he not been wearing safety goggles, he would almost certainly have suffered serious injury and loss of an eye. Although the seaman suffered injury to his face, the safety goggles played a vital role in preventing serious eye damage.

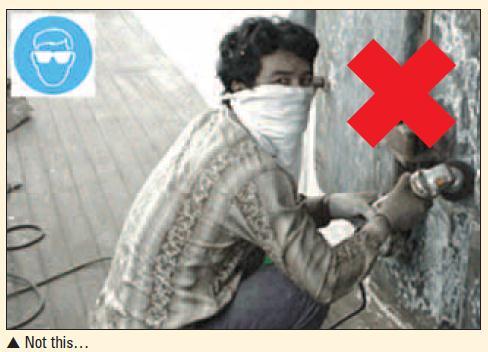

The image above shows a crew member operating a hand-held grinder without wearing eye protection. Masters should ensure that their crews are properly briefed in all safety precautions when operating grinders and other power tools. Disregard for onboard safety rules should not be tolerated.

Operators of grinding and cutting tools should assume that the disc may shatter without warning and should ensure that the guard will deflect broken prices away from themselves. The correct component parts which support and secure discs must always be used.

Engine-room workshops are usually fitted with pedestal and bench grinders. Ship inspectors sometimes find grinders on board with no safety guard fitted. These have sometimes been removed, or not used, by crew who do not fully appreciate the risk of grinding disks shattering. A properly fitted guard will shield the user from shards of grinder disk in the event that the disk shatters while in use.

The image below illustrates good working practices on board ship:

The grinder appears clean and well maintained;

Safety guards fitted;

Full-face protection available;

Good safety notices and instructions.

Additional information from the University of New South Wales, Australia:

Angle grinders are among the most dangerous tools in any workplace.

Most angle grinder injuries come from metal particles lodging in the operator's eye.

The most serious injuries come from kick-back, where the disc is thrust back violently towards the operator.

Discs can shatter or explode, sending pieces flying in all directions.

If subjected to pressures for which they were not designed, wheels can shatter at high speed, with the risk of serious injury to both operator and others nearby.

Wheel safety

Cutting wheels or discs should not be used for grinding jobs, and grinding wheels should not be used for cutting jobs.

Wheels designed for a particular revolution speed should not be used on machines of different speeds.

Wheels should be used only for the specific material and purpose for which they are designed, and according to the manufacturer's recommendations.

Wheels worn small through use should be discarded and never used on smaller machines