200660 Ballast operations

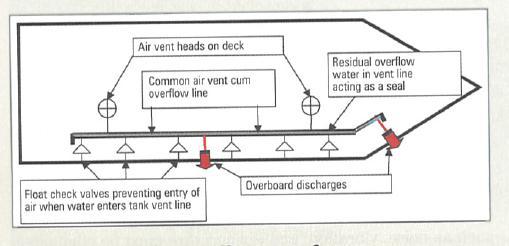

| On a large container vessel, the ballast tanks shared a common air vent-cum-overflow line, one running along each under deck passage. There were two overboard discharges on each line, one amidships and the other at the forward end, exiting the hull in way of the raised forecastle and above the waterline. Vent pipes were also led via penetrations in the upper deck to two independent vent heads. In port, it was standard procedure to shut the amidships overboard discharge valve on the shore side in order to avoid accidental discharge of ballast water overflow on to the quay, shore gantry cranes and other sensitive electrical installations. The day after departure from a turnaround port, the chief officer began deep-sea ballast water exchange. The forward tanks were emptied and refilled without incident, except that the day's operations ended with an overflow. The next morning, the chief officer resumed the operations by deballasting one of the after double bottom tanks. However, on starting the pump, he observed abnormal readings on the console ammeter and pump suction and discharge manometers. The cadet also reported intense suction on opening the tank sounding pipe. The pump was immediately stopped and investigations revealed the following:

The problem disappeared as soon as the amidships overboard valve was opened and the residual water drained from the line.

Root causes/contributory factors

Other lessons

Editor's note: Due care and diligence must always precede the commencement of any ballast operation. The ballast management plan must be fully understood and followed by the operators. The ballast record book should ideally include completed and signed checklists, calculated stability conditions, stresses, draughts and trim at every stage of ballast operations. |