200605 Mooring Injury

We picked up the pilot and proceeded to our berth with a strong NW’ly off shore wind blowing across our bow, The vessel made fast two tugs fore and aft, with tugs lines through to the centre Panama leads. The whole operation was being carried out in daylight so there was no excuse of poor lighting.

The headlines were the first line to be sent ashore, followed by tbe aft back-springs. The shore mooring gang consisted of just one person attending the moorings at each end. This did not put any strain on the ship staff to hurry up the mooring operation. The vessel was nicely alongside and in position with the loading arm. The final moorings were to be three headlines and stern lines and two springs fore and aft.

At 0814, one stern line was ashore and the master ordered this to be taken up tight and then pass out the remaining lines. Meanwhile the headlines were still being paid out. Apparently there was a problem with the forward winch drum so the lines were not being paid out as fast as normal. The stern line was already made fast aft; this line was on the drum and caused the bow to swing out away from the jetty in spite of the tug pushing it alongside. The other stern lines were being passed out. During this period, all the headlines were sent out and were tightened one at a time. But the bow was not coming alongside since the stern line was already tight so preventing it from coming in. The master asked for the stern line to be slackened by about two metres. This order was promptly executed and reported back to the master.

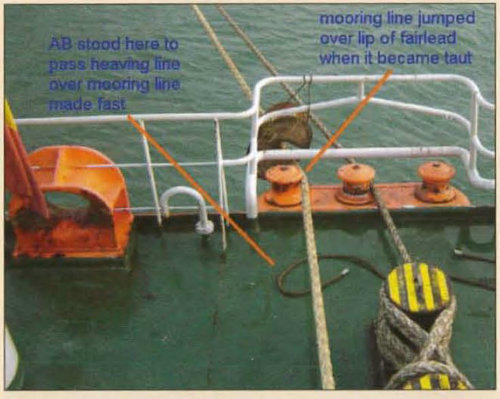

In order to send out the additional stern lines, it was necessary to pass the heaving line over the other stern line, which had been slackened. For this reason, the AB was standing next to the stern line and manipulating the heaving line over it. One moment the stern line was slack and the next it had gone tight and had too much weight on it. Before anyone realised, the stern line jumped off from under the 'lip' of the fairlead roller and hit the AB on his right knee-cap. Fortunately the blow was not hard and he escaped with a bruise and swelling, Those were treated and he could walk unhindered in a few hours. However , the main point is that there was an accident involving moorings, in spite of repeated • warnings and discussions held prior to commencing the operations.

The reason the stern line became so tight was probably due to the fact that the headlines were being tightened. This caused the bow to come alongside rapidly and the two metre slack that had been rendered aft was not enough and caused

the stern line to strain and jump from under the lip of the fairlead roller,

Lessons learnt

1. Whenever any lines are being tightened or slackened, personnel should keep well clear of the area,

2. When headlines or stern lines are tightened, proper communication should be made between the bridge and the duty officers, so that they are aware that the lines will be under strain, even though they have been slackened,

3, Mooring lines, even though they have been made fast and apparently under no strain, have to be given a wide berth. The duty officer must ensure this at all times.

Feedback Letter in Seaways March 2006

The February 2006 issue of Seaways contained a description of a seafarer sustaining a minor injury as the result of a stern line coming under tension and jumping out of its roller fairlead. He was struck in the knee by the line as he was passing a heaving line around the outside of the railings to run another stern line. The 'lessons learnt' part of the report listed the usual safe working practices that ships' crews are continually told about and inferred that the accident occurred because the crew had been careless in not following these procedures.

In my opinion, this conclusion is typical of the 'pass the buck' type of judgement that, in the words of one fictional character 'says nothing that I didn't know already and explains nothing that I wanted explained’*

As far as I can make out from the report, the seafarer in question was doing what he had to do: it was probably impossible for him to avoid being close to the mooring lines as he made another heaving line ready for throwing. What the report failed to look at is why the rope jumped out of the roller in the first place. The photograph that accompanies the report shows the stern lines passing around a type of roller that is designed to lead ropes downward from the ship's mooring deck. However, it would appear from the photograph that the mooring lines in this case seem to have been almost horizontal as they came tight and were only deflected through a shallow angle at the roller itself.

It's not surprising that the rope jumped, as the angle of the stern lines to the horizontal was too small, which could have been solved if the lines could have been shortened by running them to another quayside bollard closer to the ship's stern. However, whether or not this was an option would have depended on the bollard arrangement ashore and the ship's required position alongside, which the report does not go into. The berth on this occasion may have been particularly unsuited for the ship (the height of the wharf may have been too high or the mooring bollards were unfavourably placed).

If the ship is frequently moored in this sort of situation, the shipowner should replace the open roller leads with a closed type. Rollers leads are there to provide a fair lead for mooring ropes to pass through and even if the incident had not caused injury, it still may have damaged the railings and the rope. If a mooring line jumps out of its lead whilst the ship changes its draft or trim during cargo operations and is unseen, then it is likely to fray and could possibly part in some situations.

Although we can all occasionally be careless, and most of us at one time or another have done something fairly stupid, experienced crews are generally quite sensible in how they go about their business. In my view, accidents very often happen because some detail or other has been overlooked in the ship's operational plan and the crew are left to deal as best they can. This particular incident was a fairly minor one that fortunately appears to have no long lasting consequences but it is all too easy to quote safe working practices and then blame the crew for not following them without considering why they behaved as they did.

*The quote comes from The Caine Mutiny by Herman Wouk, a novel I can thoroughly recommend for Wouk's very perceptive (and sometimes highly amusing) descriptions of the realities of keeping good working relationships onboard a ship (or in any other society, for that matter).

Ian Clark BSc, MSc, MNI, Anglesey, Wales