200429 Safety or Security

Safety or Security

MARS Report 200429

|

I was recently aboard a well run ship that had just passed its ISPS audit. In the interests of "security", the safety of the crew (especially the engine room crew) had been compromised. The engine room escape hatch was locked from the outside. This not the first time I have seen this situation. |

|

Readers' Feedback

1

As a serving master, trading regularly through the Singapore Strait, the locking arrangement in the photograph looks very similar to an arrangement that I use. In a number of cases I have seen emergency escapes secured from the inside with no means of opening from the outside (in which case the photographer would not have seen it) however, when this is the case I have a similar arrangement fitted, and since ISPS implementation I believe this is a preferred for securing some accesses method please look at the photograph closely:-

Where the hasp is fitted to the coaming it appears to be a nut with a bolt protruding, is it not possible that within the hatch that the Bolt could be fitted with a "Butterfly" head, in order that the bolt can be released from the inside? With the bolt thus withdrawn, the hasp would be released and the hatch free to open complete with padlock still attached, thus security does not compromise safety. The only counterpoint to this with the photograph is that the bolt appears to protrude through the nut and looks as if it has been painted into place which would make it difficult to release, I would recommend that the bolt would be trimmed flush with the nut and well greased and be part of a regular maintenance (say monthly) to prove freedom of movement. By colour scheme the vessel is clearly not of the same company as my own. However, if this did raise a safety issue, the Inspector should have discussed the matter with the Master/Management of the vessel at the time for his own peace of mind, and if the arrangement is as described above he may well have received a demonstration of how it worked.

I would be pleased to hear if there is another solution which can provide the same security & safety with the same simplicity.

*********************************************************************************************

2

Looking closely at the photograph with MARS 200429 it appears that the padlock hasp is bolted to the hatch coaming. It may well be that on this well run ship the internal fixing is by wing nut or other means that can be released from inside. This is quite a common arrangement to overcome the security vs escape dilemma and in my opinion is acceptable, provided that the internal fixing is kept well lubricated and can readily be released by anybody trying to escape.

***********************************************************************************************

3

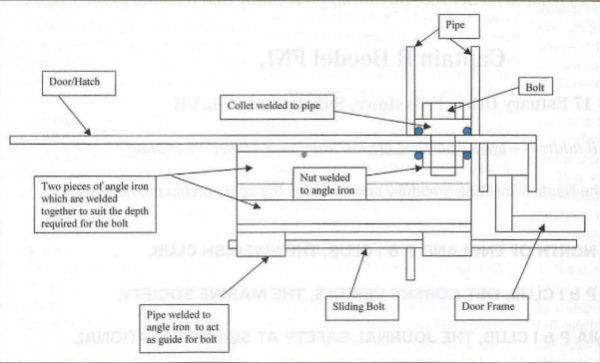

As shown in the diagram, the hatch/door can be fitted with a sliding bolt internally which is bolted to the door. To open from the inside one simply slides the bolt and opens the door in the normal way. To effect entry from the outside the bolt arrangement is bolted to the door and can be released from the outside as long as you have the appropriate key. The head of the bolt is recessed so that it is not accessible unless you have the appropriate key.

On my vessel the pipe providing the recess has been fitted with a collett at the bottom end so that it is held in place by the bolt that holds the internal sliding bolt arrangement. Ideally the pipe would be welded in place for extra strength.

With respect to doors such as the fo'c'sle and the steering flat where access is required for hydraulics to mooring winches etc. and the pump room where access is also regularly required in port, mechanical digital door locks have been fitted. These are readily available from most locksmiths and are catalogues.

**********************************************************************************************

4

The use of the padlock is obviously of great concern. It demonstrates clearly to the observer that the space is secure and, if the padlock is found to be open, then it also clearly demonstrates that someone - authorised or not - has gained access to the space below. However, I assume form the photo that the access is, in fact, an emergency exit from a space below: If so, why is it not painted red and why is it not clearly marked as such? There is an argument on the security front that says you should not identify the spaces served by any particular access as you immediately identify the purpose to the would-be bad guy. Realistically, in my opinion, the chances of the baddies gaining access to any but the most strategic of target ships - passenger vessels, tankers and gas carriers - is unlikely. From a risk assessment point of view, the terrorist threat is very low on the scale.

Notwithstanding that approach, ISPS has been forced upon the shipping world and there is a need to comply. In this particular case, a simple plastic cable tie would have been more than sufficient. The outward appearance is of secure access control and provides an immediate visual indication of a breach of that control. From the safety point of view, anyone requiring egress through the hatch would easily break the cable tie with a good push from below.

Very simple, very cheap and very effective. Next time you travel on the underground, look at the seat cushions. On many of the rolling stock you will find that they are secured with cable ties. In the event of a terrorist threat, it is easy for the search teams to determine if there has been a breach of security simply by looking at the security of the cable ties.

If you want to increase the efficiency of a cable tie system - for example, where a space may be regularly visited for maintenance, numbered seals of the same format and strength are readily available. As seems to be the case on many ships, the advice given for compliance has not been tempered by a practical seamanlike approach - but what's new ?

*********************************************************************************************

5

A simple metal box with dimensions greater than the radius of the handle welded over the top of the dog with a hinged flap top and padlock attachment was one answer. Removal of the top part of the dog and replacement with a "key nut" was another. Both options allow for the dog to be operated from below but not from above thus ensuring that the direction of escape is unhindered.

*********************************************************************************************

6

The problem of locking up access doors/escape hatches is a serious one as it may trap people. Even doors and escape hatches with devices to release locking hasps and staples from within are not really satisfactory as the entrapped may be worried and in a hurry - so much so that the release of the hasp and a stable from within is forgotten or misunderstood. In panic for ones life, rational thought can be sacrificed.

The ISPS Code is quite well written. Part B Restricted Areas (Para. 9.18 etc) does not require any place to be 'locked'. Locking such areas is not made mandatory. Consultants with little experience of seafaring or practical ship management at a senior level have been drafting plans requiring many spaces in the ship to be locked up - even at Security 1. This is not an ISPS requirement. So the locking problem is a self-inflicted measure voluntarily imposed upon their seafarers by ship managers.

Once locking up has been written into a Ship Security Plan and it has been approved by a Recognised Security Organisation, it must be complied with. However, there are alternatives. Thus the ISPS, in respect of restricted areas, calls for -

- 'security measures to control access',

- 'to prevent unauthorised access',

- 'clearly established policies and procedures to control access',

- 'access ?. is restricted',

- 'may include locking or securing' (there is no compulsion to lock up).

Thus I presume compliance can be achieved by restricting access to the ship at the gangway. This should be sufficient and it has served our industry well for a long time. And, if a further step is required, sealing the access hasp and stable by plastic tape - so lightly made that it can be easily broken from within, so weather resistant that it will survive and so brightly coloured that any removal or breakage will be noticed by patrol men indicating an unauthorised access. Thus, I believe, the solution is a Ship Security Plan Amendment to ban the locking up of people inside and below.

**********************************************************************************************

7

I regrettably have to question the statement that the incident was on a "well run" ship. The missing dog on the hatch shows poor maintenance of the vessel's watertight integrity. (See number 5 above which suggests the removal of the top part of the dog and replacement with a key nut. Ed).

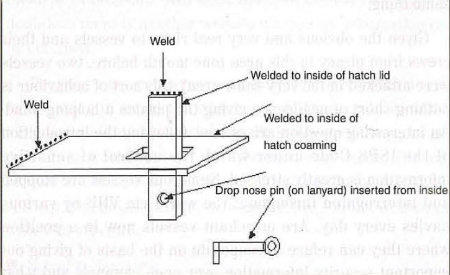

I agree that the padlocking of the hatch on the outside is crazy. On my vessel, I asked the engineers to weld lugs on the inside of the hatch with a pin holding the hatch shut. The pin could easily be removed from the inside should the hatch be needed as an escape route. My arrangement is not ideal however as it means that, should you require to open the hatch from the outside to search for missing crew or allow access for firefighting, would be a problem. I have planned that if the hatch needed to be opened, we would use oxy-acetylene to cut the hatch in way of the lugs. I admit that this would slow down the opening of the hatch but I have been unable to come up with a better solution.

**********************************************************************************************

8

I view with horror the photo of a padlocked escape trunk. This shows a complete lack of thought by the ship's officers, the shipping company, and the ISM/ISPS auditors. Having operated for most of my career in the high-piracy areas of South-East Asia, it has been second nature on every ship to secure escapes from inside with quick-release methods. For escape scuttles, these might be a nylon ratchet strap or chain binder from the hatch's underside to the ladder rungs. For weather doors, these might be a large throw-bolt or a quick-release tiedown on a door lever. However, all of these require crew training and commitment and frequent inspection by the Security Officer.

There are many easy methods to provide both safety and security. The photo shows the complete abandonment of safety in favour of security.

**********************************************************************************************

9

This is how we secure our hatches onboard. The outer handle is cropped to allow it to rotate within the cover when opened from inside. If the hatch is to be opened from outside the extension handle is fitted to the cropped handle once the hinged cover is unlocked. This could be simplified by fitting a larger cover which would allow an uncropped handle to rotate.

********************************************************************************************

10

So, here we go on one of the many anomalies of securing a hatch to prevent unauthorized entry. First we have to consider that any door, hatch, window or whatever means of access or exit - especially those designated as emergency exits must be capable of being opened from the inside. If it means that someone with a key has to open it from the outside then this practice is completely unacceptable. I am sorry, but I do not agree with the proposal advocated in the August issue of SEAWAYS.

The hatch in question appears to be a non-watertight one. Assuming this was an Engine Room escape hatch then it would be best secured from the inside, thus allowing those attempting to get out to achieve their escape. By all means, use a padlock in port but when all the Mandarins, Kings and Generals have satisfied themselves that all is in order, remove the padlock and allow exit only from the inside. The proposed wing nut scheme leaves doubt in my mind for the reason that the nature of the beast adds yet another impediment to maintenance by the fact that greasing and inspection will be required by some schedule or other. Also, if this is a hatch at the top of a vertical ladder, possibly in the dark, we have now compounded the matter with the difficulty of a one handed operation.

Here is a simple sketch showing a very simple method of preventing access from the outside but allowing easy exit from the inside. Easy to fit and easy to operate.