200160 Lifeboat Falls incorrectly Clamped

Lifeboat Falls incorrectly Clamped

Report No. 200160

|

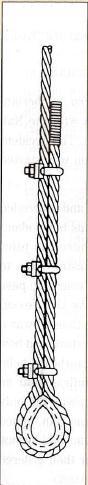

Whilst travelling as a passenger on a cruise ship I noticed that all the lifeboat falls had been clamped with only two bulldog grips (see attached picture). My experience in this area led me to the conclusion that the method used was incorrect. First of all there were only two grips on each termination. A minimum of three, and preferably more, are required on lifting or safety equipment. Secondly, the lower of the two grips in the photograph has been applied in the wrong direction. All grips should be applied in the same direction with the bridge (or saddle) on the working/hauling part of the wire. All of the other terminations had been made up with the same faults or variations on these faults. It is a well-published fact that empirical and carefully monitored tests show that two grips only, both applied in the correct direction will generally produce a slip load of about 60% of the wire's nominal breaking load (NBL). Two grips applied in opposing directions will produce a slip load of about 50%. It could be possible that these slip loads had been taken into account when the falls were rigged and that the eyes with two grips in any configuration have been found to meet the required safety factor at the termination. I doubted that this was the case because the application on the eyes of these falls was randomly different and wrong in each instance. In other words, if two grips had been found to be sufficient, and approved as same, it would seem reasonable to suppose that the correct application of two grips would be identical on all the wires. |

|

On further enquiry, the management of the shipping company confirmed that a dynamic 115% overload test had been successfully carried out under the supervision of a Class Surveyor. However, I still doubt that the test was carried out on all 16 differently made up falls. It may be that the test carried out with the eyes made up with two grips in the correct direction did in fact prove to be acceptable. One way or another, these falls were not properly made up and this should be corrected.

The correct method of fitting wire clips is shown in the diagram. The bridge of the grip should be fitted on the working part of the rope and the "U" bolt on the rope tail or "dead end" of the rope. The grips should not alternate in position. The table below shows the recommended minimum number of wire rope grips for each size of rope.

|

Diameter of rope in mm. |

Minimum number of grips |

|

up to and including 19 |

3 |

|

over 19 up to and including 32 |

4 |

|

over 32 up to and including 38 |

5 |

|

over 38 up to and including 44 |

6 |

|

over 44 up to and including 56 |

7 |

The grips should be spaced at a distance of approximately 6 rope diameters. Care must be taken to ensure that the grips are properly tightened. If properly made up , with the recommended number of grips, correctly spaced and tightened, and all the grips placed correctly, such a termination would be expected to hold at least 80% of the minimum breaking load of the rope. This figure falls to 75% if no thimble is used.

The correct method of applying grips is shown below.

It is understood that the UK Marine and Coastguard Agency (MCA) intend to issue an "M" Notice in the near future which will prohibit the use of grips on lifesaving equipment. I believe that an instruction has already been issued to their Surveyors to this effect.